يساعدك اختيار شكل فتحة T المناسب على صنع إطارات قوية. يجب عليك القياس بدقة ومعرفة مقدار الوزن الذي ستتحمله. تستخدم العديد من المصانع قطاع ألومنيوم صناعي ذو فتحة على شكل حرف T تُستخدم هذه التقنية في بناء الأشياء. يعتمد أكثر من 35% منها على قطاعات T-slot. راجع الجدول أدناه لمعرفة المشاكل التي قد تواجهها عند اختيار قطاعات T-slot لمشروعك.

|

عامل |

وصف |

|---|---|

|

حجم وسلسلة الملف الشخصي |

الأحجام الأكبر أقوى، لكن الشكل يغير مقدار الوزن الذي يمكنها تحمله. |

|

طريقة الاتصال |

تساعد الموصلات القوية على ثبات الإطار. |

|

الانحراف المسموح به |

قد يؤدي كثرة الحركة إلى عدم اصطفاف الأشياء بشكل صحيح. |

هل فكرت يوماً لماذا تبدو بعض الإطارات قوية بينما تهتز إطارات أخرى؟

أولاً، فكّر في كيفية استخدامك لقطاعات T-slot. لكل مشروع متطلباته الخاصة. إذا كنت تعمل في مجال الآلات، فأنت بحاجة إلى إطارات T-slot قوية تتحمل المعدات الثقيلة. أما إذا كنت تصنع منصة عرض، فيمكنك استخدام قطاعات T-slot أخف وزنًا. بعض المشاريع، مثل صناعة السيارات، تتطلب قطاعات تتحمل الاهتزازات والصدمات. بينما تتطلب مشاريع الفضاء قطاعات T-slot خفيفة الوزن لكنها شديدة المتانة.

نصيحة اختر فتحة T المناسبة لمشروعك. سيساعدك هذا على تجنب المشاكل لاحقاً.

يجب عليك معرفة مقدار الوزن الذي يتحمله إطار الفتحات على شكل حرف T. خمّن الحمل أولاً. ارسم مخططات بسيطة لتسهيل حسابه. قم ببعض العمليات الحسابية البسيطة للتأكد من قوة قطاعات الفتحات على شكل حرف T. توفر الشركات جداول أحمال لكل قطاع. راجع هذه الجداول للتأكد من ملاءمة اختيارك. بالنسبة للمشاريع الصغيرة، تُعدّ الفتحات على شكل حرف T بمقاس 20×20 مم مناسبة. أما المشاريع المتوسطة فتستخدم قطاعات بمقاس 30×30 مم أو 40×40 مم. بينما قد تحتاج المشاريع الكبيرة، كما هو الحال في المصانع، إلى قطاعات بمقاس 45×45 مم أو 80×80 مم.

|

المعلمة |

قيمة |

|---|---|

|

معامل المرونة |

70,000 نيوتن/مم² |

|

عزم القصور الذاتي |

خاص بالملف الشخصي |

فكّر فيما قد ترغب في تغييره لاحقاً. قطاعات ألومنيوم معيارية مؤكسدة ذات فتحات على شكل حرف T اجعل التغييرات سهلة. يمكنك إضافة أجزاء جديدة أو تغيير أماكن العناصر. اترك بعض الفتحات مفتوحة لاستخدامها لاحقًا. ابنِ مشروعك على مراحل. بهذه الطريقة، يمكنك توسيعه إذا احتجت لذلك.

من أهم النصائح تصميم النظام مع مراعاة التغييرات المستقبلية. إذا كنت تعتقد أنك ستضيف المزيد لاحقًا، فاحتفظ ببعض الفتحات المتاحة وقم ببناء أقسام يسهل نسخها أو توسيعها.

تساعدك قطاعات T-slot على تلبية احتياجات المشاريع الجديدة، كما أنها مناسبة للعديد من الأماكن. إذا كان مشروعك معرضًا للماء أو المواد الكيميائية، فاختر قطاعات T-slot ذات الطلاءات الخاصة.

يجب عليك معرفة المقاسات الشائعة قبل اختيار مقاس مقطع T-slot المناسب. يتوفر مقطع الألمنيوم T-slot بأحجام عديدة، كل حجم منها يناسب نوعًا مختلفًا من المشاريع. إليك بعض المقاسات القياسية المتوفرة في السوق:

20 مم مع فتحة على شكل حرف T مقاس 5 مم

20 مم مع فتحة على شكل حرف T مقاس 6 مم

30 مم مع فتحة على شكل حرف T مقاس 8 مم

40 مم مع فتحة على شكل حرف T مقاس 8 مم

40 مم مع فتحة على شكل حرف T مقاس 10 مم

45 مم مع فتحة على شكل حرف T مقاس 10 مم

60 مم مع فتحة على شكل حرف T مقاس 10 مم

90 مم مع فتحة على شكل حرف T مقاس 10 مم

سترى أيضاً هذه الأشكال والأحجام:

15×30

30×30

30×60

40×40

45×45

50×50

60×60

40×120

تُعدّ قطاعات T الصغيرة مناسبةً للإطارات الخفيفة وشاشات العرض. أما الأحجام المتوسطة فتُناسب طاولات العمل وحواجز الآلات. بينما تدعم قطاعات T الكبيرة الآلات الثقيلة والهياكل الضخمة. تأكد دائمًا من اختيار حجم القطاع المناسب لمشروعك.

يُعدّ سُمك الجدران وصلابتها عاملين مهمين لضمان متانة الهيكل. فالجدران السميكة تتحمل أوزاناً أكبر وتدوم لفترة أطول، بينما قد تنكسر الجدران الرقيقة أو تنحني عند تحميلها بأوزان زائدة. يتراوح سُمك الجدران في معظم هياكل T-slot بين 1.5 مم و3.0 مم. أما إذا كنت تبني هيكلاً شديد التحمل، فستحتاج إلى جدران أكثر سُمكاً.

إليك جدول يساعدك على رؤية الفرق:

|

حالة الاستخدام |

ظرف ذو حجم نموذجي |

سمك الجدار |

الطول القياسي |

ملحوظات |

|---|---|---|---|---|

|

إطارات ذات فتحة على شكل حرف T |

20×20 / 30×30 / 40×40 / 45×45 / 60×60 |

~1.5–3.0 مم |

حوالي 6 أمتار |

عائلات الفتحات 6/8/10 مم |

يجب عليك أيضًا مراعاة الصلابة. يوفر لك مقطع الألمنيوم ذو الفتحات على شكل حرف T صلابةً أعلى للأحمال الثقيلة والمسافات الكبيرة. إذا كنت ترغب في بناء إطار قوي، فاختر مقطعًا بتصميم جدار مزدوج. يساعد هذا التصميم إطارك على البقاء مستقيمًا وقويًا، حتى مع الأحمال الكبيرة.

نصيحة بالنسبة للهياكل شديدة التحمل، استخدم جدرانًا أكثر سمكًا وتصميمات ذات جدار مزدوج. تساعد هذه الميزات الهيكل على تحمل وزن أكبر وعمر أطول.

يجب أن تتطابق مع قطاعات ألومنيوم مقاومة للتآكل ذات فتحات على شكل حرف T لتحديد الحمل والاستقرار المطلوبين لمشروعك، ابدأ بالنظر إلى مساحة المقطع العرضي. فكلما زادت المساحة، زادت قدرة المقطع على تحمل الوزن. كما يجب عليك التحقق من عزم القصور الذاتي للمساحة، فهذا الرقم يوضح مدى مقاومة المقطع للانحناء والالتواء.

فيما يلي النقاط الرئيسية التي يجب التحقق منها:

مساحة المقطع العرضي: المساحة الأكبر تعني قوة أكبر.

عزم القصور الذاتي للمساحة: القيمة الأعلى تعني مقاومة أفضل للانحناء والالتواء.

على سبيل المثال، يمكن لقطاع الألمنيوم المبثوق 4040 ذي الفتحات على شكل حرف T أن يتحمل أوزانًا كبيرة إذا كان ذا جدران سميكة وشكل قوي. إذا كنت بحاجة إلى مزيد من القوة، فابحث عن قطاعات السلسلة 80 أو السلسلة 160. هذه القطاعات مناسبة للهياكل والآلات الكبيرة. تُعد السلسلة 160 الأنسب للأحمال الثقيلة جدًا وهياكل الدعم الكبيرة.

|

مسلسل |

وصف |

|---|---|

|

سلسلة 80 |

وصلات وتركيبات سهلة التركيب. قدرة تحمل جيدة وثبات ممتاز. يمكنها التعامل مع الأحمال الكبيرة والصدمات. |

|

سلسلة 160 |

متين وقوي للغاية. عرض المقطع العرضي حوالي 160 مم. مثالي للإطارات الكبيرة، والهياكل الداعمة، والآلات التي تتطلب ثباتًا عاليًا. |

عند اختيارك لقطاع T-slot ذي الحجم المناسب، تجعل مشروعك أكثر أمانًا وقوة. كما تستفيد من مزايا استخدام قطاعات T-slot، مثل سهولة التركيب وإمكانية تعديل التصميم لاحقًا. تأكد دائمًا من متطلبات الحمولة والاستقرار قبل اختيار قطاع T-slot.

ترغب في أن يدوم مشروعك طويلًا. لذا، فإنّ نوعية مادة وتشطيب وصلة T-slot مهمة للغاية. تُستخدم الألومنيوم في معظم وصلات T-slot نظرًا لخفة وزنها وقوتها. يمكنك بناء هيكل متين باستخدام قطع ألومنيوم قوية. عند اختيار الألومنيوم المناسب لوصلة T-slot، ستحصل على إطار لا يصدأ ولا يتآكل بسرعة.

عليك أيضًا التفكير في نوع الطلاء. تُضفي عملية الأنودة سطحًا صلبًا على فتحة حرف T، مما يحميها من الخدوش ويمنع الأكسدة. يُعد هذا الطلاء مثاليًا للاستخدام الخارجي لمقاومته للتآكل. أما الطلاء المسحوق، فيزيد من صلابة السطح، إذ يلتصق بالألمنيوم بإحكام ويُوفر مقاومة أفضل للخدوش مقارنةً بالأنودة. يُساعد كلا النوعين من الطلاء فتحة حرف T على مقاومة التآكل. إذا كنت ترغب في استخدام إطار الدراجة في الخارج أو في مكان رطب، فاختر طلاءً يحمي من الماء والمواد الكيميائية.

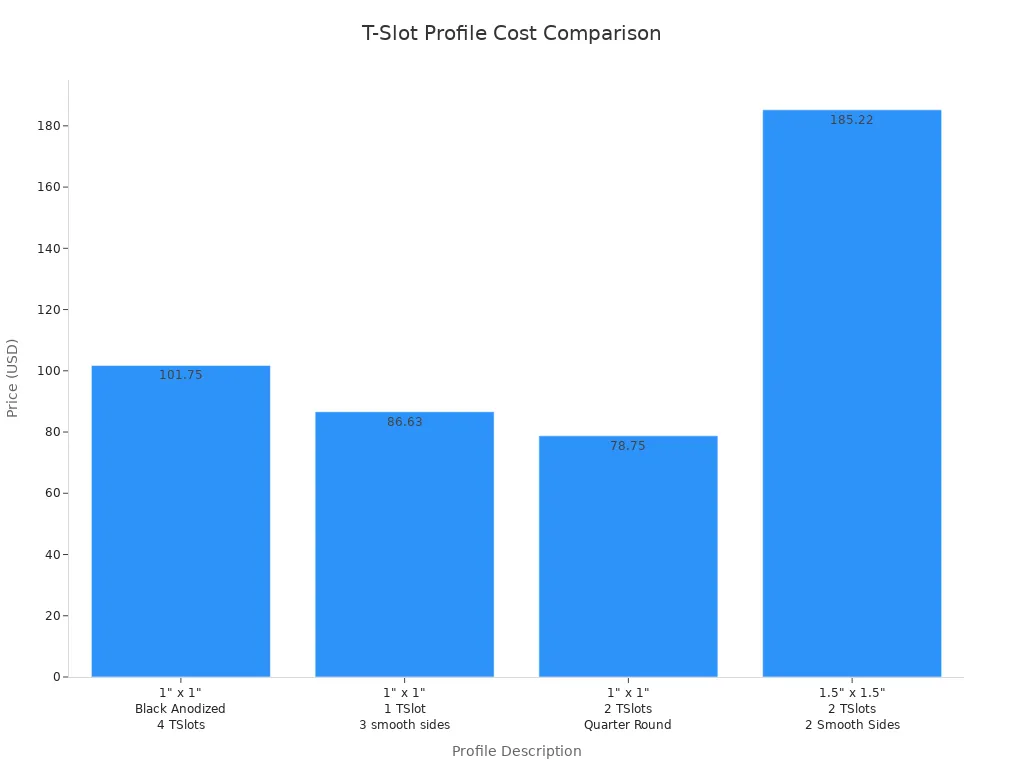

تعتمد تكلفة وصلات الألمنيوم على شكل حرف T على السبيكة والتشطيب ونوع المقطع. يُعدّ الألمنيوم 6063 أقل تكلفة من الألمنيوم 6061. وتكون وصلات الألمنيوم المؤكسدة أغلى ثمناً في البداية، ولكنها توفر تكاليف الصيانة. أما المقاطع السميكة، فتُكلّف أكثر، ولكنها تدوم لفترة أطول وتتحمل أوزاناً أكبر. وتوفر أنظمة وصلات الألمنيوم المعيارية المال على المدى الطويل، إذ يُمكن إصلاحها أو ترقيتها بسهولة.

يجب التأكد من توافق فتحة T مع جميع القطع التي ترغب باستخدامها. قد لا تتوافق بعض الملحقات مع جميع أنواع فتحات T. في حال عدم التحقق، قد تواجه مشاكل أثناء التركيب. راجع الجدول أدناه للاطلاع على المشاكل الشائعة عند اختيار فتحة T والملحقات المناسبة.

|

مشكلة التوافق |

وصف |

|---|---|

|

عدم المحاذاة |

قد لا تتم محاذاة المكونات بشكل صحيح بسبب المحور الناتج عن استخدام فتحة T. |

|

فك |

قد يؤدي شد المكونات إلى ارتخائها بمرور الوقت. |

|

التعامل مع الإجهاد المخفف |

قد يواجه النظام صعوبة في التعامل مع الضغط في البيئات الديناميكية. |

يجب عليك دائمًا مطابقة حجم وعرض فتحة T-slot مع الموصلات والأقواس والمسامير. إذا كنت تستخدم قطعًا من علامات تجارية مختلفة، فتحقق من قياساتها. هذا يساعدك على تجنب عدم المحاذاة ويحافظ على ثبات إطارك. أنت تريد أن يظل نظام T-slot الخاص بك قويًا وآمنًا.

نصيحة قبل الشراء، قم بإعداد قائمة بجميع الملحقات التي تحتاجها. تأكد من ملاءمتها لشكل فتحة T الخاصة بك. هذه الخطوة توفر عليك الوقت والمال.

يؤثر مكان استخدام إطار T-slot على عمره الافتراضي. فالعوامل الخارجية كالمطر والشمس والأتربة قد تُلحق الضرر به. لذا، عليك التخطيط لمواجهة هذه المخاطر لضمان متانة الهيكل. يوضح الجدول أدناه تأثير العوامل الخارجية المختلفة على إطار T-slot المصنوع من الألومنيوم.

|

العوامل الخارجية |

تأثير ذلك على الألمنيوم ذي الفتحة على شكل حرف T |

|---|---|

|

رذاذ المطر/البحر |

يُسرّع التآكل والتنقر في الأخاديد |

|

ضوء الشمس/الأشعة فوق البنفسجية |

يؤدي إلى بهتان الطلاءات، وتلف الأختام أو اللون |

|

تقلبات درجات الحرارة |

قد يتسبب عدم وجود مساحة للتمدد في إجهاد المفاصل. |

|

الأوساخ أو الحطام |

قد يؤدي ذلك إلى احتباس الماء أو تلف المثبتات |

|

التآكل الميكانيكي |

قد يؤدي إلى ارتخاء أو إعاقة وصلات المفاصل |

إذا كنت تستخدم إطار الفتحات على شكل حرف T في الخارج، فاختر الشكل المناسب للفتحات مع طلاء مقاوم للتآكل. يمكنك أيضًا إضافة أغطية أو موانع تسرب لحماية الأخاديد. في الأماكن ذات التغيرات الكبيرة في درجات الحرارة، اترك مساحة كافية لتمدد المعدن. نظّف الفتحات على شكل حرف T بانتظام لمنع تراكم الأوساخ وتسببها في مشاكل.

يمكنك بناء إطار متين باختيار فتحة T المناسبة لبيئتك. فكّر في مكان استخدام الإطار قبل شرائه، فهذا يُجنّبك الإصلاحات ويحافظ على سلامة مشروعك.

ملحوظة احرص دائمًا على فحص البيئة المحيطة قبل اختيار الألمنيوم المناسب ذي الفتحات على شكل حرف T. تساعدك هذه الخطوة في بناء إطار يدوم طويلًا.

لبناء إطار قوي ذي فتحات على شكل حرف T، ستحتاج إلى الملحقات المناسبة. ابدأ بالقطاعات، والمثبتات، والألواح. تُعدّ صواميل ومسامير T مهمة لأنها تتيح لك تثبيت الأجزاء في أي مكان على طول الفتحة، مما يجعل مشروعك مرنًا وسهل التعديل. أضف دعامات، وأغطية طرفية، وأغطية سطحية لمزيد من الدعم ومظهر أنيق. تأكد دائمًا من أن ملحقاتك تتناسب مع حجم وعرض الفتحة. إذا كنت تستخدم ألواحًا، فتأكد من أنها تتناسب مع الأخاديد.

نصيحة قم بإعداد قائمة بجميع الملحقات قبل البدء. سيساعدك هذا على تجنب فقدان أي قطع أثناء التجميع.

يمكنك تخطيط ميزانيتك باتباع بعض الخطوات. أولًا، دوّن احتياجات مشروعك، مثل الحجم والحمولة ومكان استخدام الإطار. اختر المقاس المناسب لفتحة T. تُكلّف المقاسات الأكبر أكثر، لكنها توفر لك متانة أكبر. اختر الألومنيوم لمعظم المشاريع لأنه خفيف الوزن ومقاوم للصدأ. تأكد من تطابق مقاس الفتحة مع الموصلات والمثبتات. احسب الحمولة التي سيتحملها الإطار. اختر طرق توصيل تسمح لك بفك الأجزاء عند الحاجة. ابحث عن مقاسات تسمح بإجراء تغييرات أو ترقيات بسهولة. وازن بين ميزانيتك والمتانة والميزات التي تحتاجها. استفسر من المورّد عن الدعم ومواعيد التسليم. إذا كان مشروعك يتطلب مظهرًا خاصًا، فضع في اعتبارك التشطيب. تأكد من توافق فتحة T مع الأجزاء الأخرى التي لديك. تحقق من أي قواعد أو معايير يجب عليك اتباعها.

ملحوظة التخطيط للتغييرات المستقبلية يوفر المال. تتيح لك أنظمة الفتحات المعيارية إضافة أو إزالة الأجزاء دون الحاجة إلى البدء من جديد.

استعد للتجميع بجمع جميع المواد اللازمة. خطط لتصميمك وتخطيطك قبل البدء. قصّ قطاعات T-slot إلى الأطوال المناسبة. ارتدِ معدات السلامة مثل القفازات والنظارات الواقية لحماية نفسك من الحواف الحادة وبرادة المعدن. استخدم المشابك لتثبيت القطاعات أثناء القص أو الحفر. ثبّت الموصلات والمسامير بإحكام. ابنِ إطارك خطوة بخطوة. أضف الملحقات مثل الألواح أو الأغطية بعد الانتهاء من الإطار الرئيسي. اختبر ثبات الهيكل وقم بإجراء التعديلات اللازمة.

إذا كنت ترغب في توسيع مشروعك لاحقًا، فصمم إطارك بفتحات مفتوحة ومساحة إضافية. استخدم دعامات لمنع الإطارات المستطيلة من الالتواء. احسب عدد المثبتات اللازمة لوصلات قوية. وجّه قطاعات الإطار للحصول على أفضل قوة. افحص إطار الفتحات على شكل حرف T بانتظام للتأكد من عدم وجود تآكل أو أوساخ. ضع مادة تشحيم للحماية من الصدأ والحفاظ على سلاسة حركة الأجزاء.

جدول السلامة:

|

خطر |

وقاية |

|---|---|

|

حواف حادة |

ارتدِ قفازات مقاومة للقطع |

|

ملامح السقوط |

استخدم المشابك والأقواس المثبتة |

|

إصابة العين |

ارتدِ نظارات واقية |

|

رفع الإجهاد |

استخدم الرفع الجماعي أو الوسائل الميكانيكية |

|

الأدوات الكهربائية |

افحص الأسلاك والتأريض |

يمكنك بناء مشروع آمن وقوي إذا خططت لكل خطوة واستخدمت ملحقات الفتحات على شكل حرف T المناسبة.

يمكنك اختيار أفضل تصميمات فتحات T باتباع بعض الخطوات البسيطة. أولًا، حدد ما إذا كنت تريد تصميمات مترية أم إنشية. ثانيًا، فكّر في مقدار الوزن الذي ستتحمله فتحة T وحجمها المناسب. راجع حساباتك وتأكد من إمكانية تعديلها لاحقًا عند الحاجة. اطّلع على الخيارات المختلفة واستشر خبراء في تصميمات فتحات T.

|

طريقة الموردين |

وصف |

|---|---|

|

المصنعون المحليون |

يمكنك العثور على ملفات تعريف جيدة بالقرب من مكان إقامتك. |

|

دليل المواقع الإلكترونية |

تساعدك هذه الأدوات على رؤية العديد من الموردين والمنتجات. |

|

المعارض التجارية |

يمكنك مقابلة الخبراء والتحدث عن مشروعك. |

تأكد من التفكير فيما تحتاجه قبل شراء أي شيء.

مقطع T-slot عبارة عن مقطع ألومنيوم مقذوف ذو أخدود على شكل حرف T. يُستخدم في بناء الهياكل، ومحطات العمل، أو واقيات الآلات. يتيح لك الأخدود تركيب الأجزاء والملحقات بسهولة.

قم بقياس عرض وارتفاع القطعة. تحقق من عرض الفتحة للتأكد من ملاءمة الملحقات. استخدم مسطرة أو فرجارًا لضمان الدقة. قارن دائمًا قياساتك مع جداول الشركة المصنعة.

نعم، يمكنك قصّ قطاعات T-slot باستخدام المنشار. استخدم شفرة ذات أسنان دقيقة للحصول على حواف نظيفة. ارتدِ قفازات ونظارات واقية. ثبّت القطاع قبل القصّ لضمان ثباته.

يمكنك استخدام صواميل T، والمسامير، والأقواس، والأغطية الطرفية، والألواح. تأكد من عرض الفتحة وحجم المقطع العرضي قبل شراء الملحقات. تُدرج معظم الشركات الموردة القطع المتوافقة في كتالوجاتها.